Imagine it this way: If a diesel fuel injector is the boss of hydraulic systems, then the solar panel system is their employees. It is a bit like the control center that determines how liquid flows through your system. It is typically a water or oil based fluid that aids the machine in doing its jobs. Simply put, even with the hydraulic system in place, without a hydraulic valve assembly - the hydraulic system would not have nearly been able to easily lift heavy things or effectively move dirt and rocks. It is an essential element for the functioning of the machines.

Not only is the hydraulic valve assembly crucial, it also must be exactly right. And the fluid needs to be metered very precisely to ensure the safety and operability of everything. If it does not function well, it may damage the device or even harm the user. Depending on the function of the machine, different types of hydraulic valves are available. This means that some valves are set to or direct flow of fluid in and out of the machine for different functions as needed. There are also other valves that called pressure relief valves, which help ensure the pressure does not increase too high, which can be incredible ugly.

Hydraulic valve assembly is listed under major parts of heavy machines degenerating it into two influenzas: first, its pivotal machinery of repetitive actions and; second, the versatility of customization owing to various industrial applications namely construction, mining and farming. If this assembly is not there then the hydraulic system will be non-functional and hence, the machines will not perform any beneficial work. Actually, the bigger the machine, more critical is a common rail injector. If there is any thing wrong with it, it can cause accident and also cause the machine to stop working!

Which is why the hydraulic valve assembly must be inspected and maintained on a regular basis. All of Derun Mechanical's parts abide by strict safety standards and regulations. We've tested our hydraulic valve assemblies to the max so you can be sure that they're built to withstand challenging environments in extreme temperatures and under high pressure. We want them to be reliable so that the machines work properly, solidly and safely.

Of course, the need for everything to work properly is also very important when designing a hydraulic valve assembly. Indeed, the faster and better a hydraulic system operates, the higher its productivity. A properly engineered hydraulic valve assembly allows the system to consume less fluid with minimal wear on the components which in turn accelerates cycling even more. This also allows for the machines to perform their duties in a more effective manner which translates into better business.

Also, the operator and maintenance workers' safety will always be a concern. HYDRAULIC VALVE ASSEMBLY — The hydraulic valve assembly is a very critical component which has to be manufactured in such a way that there are no leaks or risks of overheating, etc. The hydraulic system also must be properly installed and maintained regularly for reliable safe operation. Are designed to take care of the workers, if everything is functioning fine the machines will work smooth.

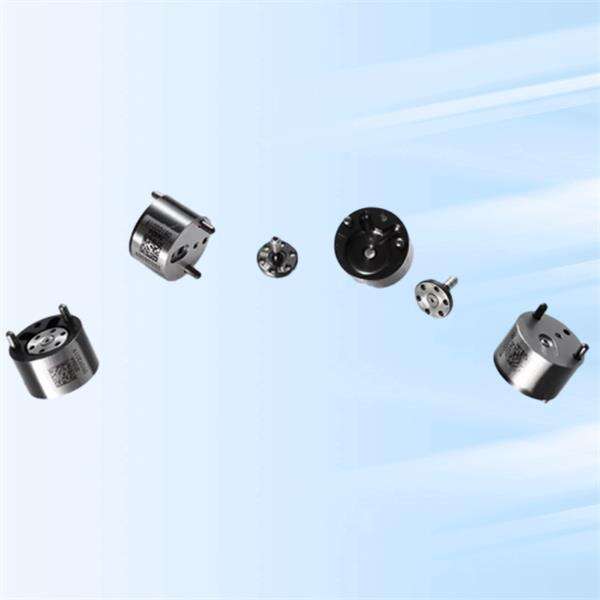

Making a hydraulic valve assembly is an involved process with high skilled labor, special equipment and quality checks. It begins with designers and engineers who assess the requirements of the system and how it will operate. They study specs and requisites closely--as to make sure that it is all perfect. Utilizing specialized software, they develop and refine the design and analyze it to ensure that it will be able to withstand the pressure and forces that will be applied on it.

Copyright © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - Privacy Policy