There was even a time when cars were not powered by gasoline engines as they are today. There were many methods of propulsion for cars in those days. However, the majority of vehicles on our roads today rely on gasoline engines that need something to burn in order to function. But how does the fuel get into the engine to make a car go? The issue occurs due to a critical component known as the လောင်စာထိုးဆေးထိုးအဆို့ရှင်. This component plays a critical role in a functioning modern fuel injection system and keeps the vehicle operating properly.

There are several different components of a modern fuel injection system, which interact with one another. These components ensure that the engine always gets an optimal amount of fuel to function properly. They function quickly and efficiently to keep the engine running with ease so the car drives as it should. Now, one of the most crucial components in this set-up is a fuel injection air control valve. This valve regulates the amount of air that is allowed into the engine along with a corresponding amount of fuel. The right amount of air and fuel ensures optimum engine performance.

The fuel injector workings air control valves avoid wastage of fuel by use. They regulate how much air comes into the engine, which optimizes the burning process (called combustion). This essentially means that the engine can produce an equal power output while consuming lesser fuel. You're literally getting more bang for your buck! This does not just translate into a more sustainable world as less fuel is consumed, but it can also contribute to your pockets through reduced gas expenditures —something that many drivers enjoy.

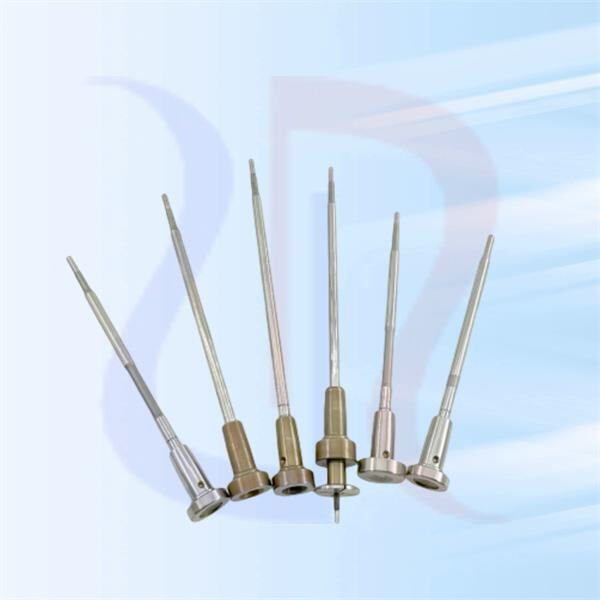

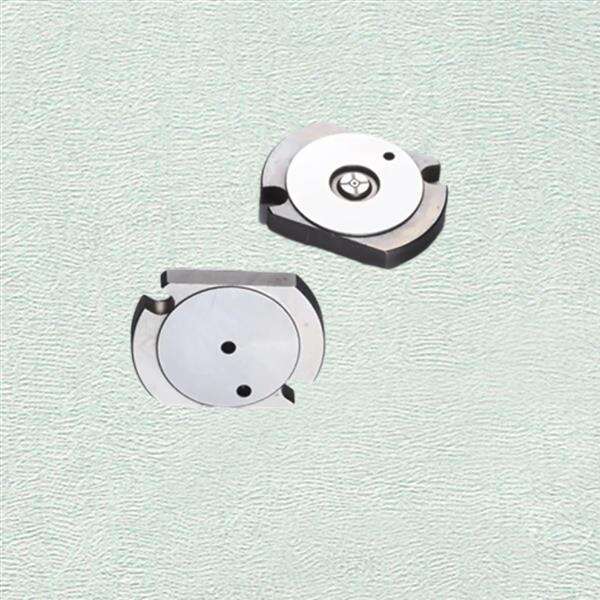

The air control valves used with fuel injection are pivotal to controlling the amount of air that enters the engine's combustion chamber. They do so by opening and closing a small section known as the plunger. The actuator is connected to the plunger and it, in turn, is controlled by the engine control computer. So, whenever the computer senses the requirement of extra air for the engine, it signals to the actuator which in turn opens up the plunger. That gives the engine an increased air intake, increasing its efficiency and also helping teh car drive better. You can imagine it as a person taking bigger breaths to run faster!

Fuel injection air control valves can wear down and malfunction just like any other component in an engine. This results in many issues like poor engine power, unnecessary fuel consumption, or even possible engine damage. Common issues that may occur include a clogged air filter, damaged or broken vacuum lines, a worn actuator diaphragm, and faulty solenoids. For a well-running engine and reliable vehicle, remember to take care of these components!

Just like cleaning the air control valve of your fuel injection, it is important to keep your FICV free from any dirt or debris that might hinder its operations. This is why maintenance is so important, it helps prevent problems, and more importantly helps your engine run the way it was designed. If you are having any trouble with your cars performance, be sure to get your fuel injection system checked by a professional during the inspection. Paying less attention to your automotive repair now will usually lead to a much larger body of perfectness come into performance later.

မူပိုင်ခွင့် © Guangzhou Derun Mechanical & Electrical Fittings Co., Ltd All Rights Reserved - ကိုယ်ရေးအချက်အလက်ပေါ်လစီ